|

ItsyBitsy M0 Synth | Sigma-6 Voice Module A DIY project by M.J. Bauer |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

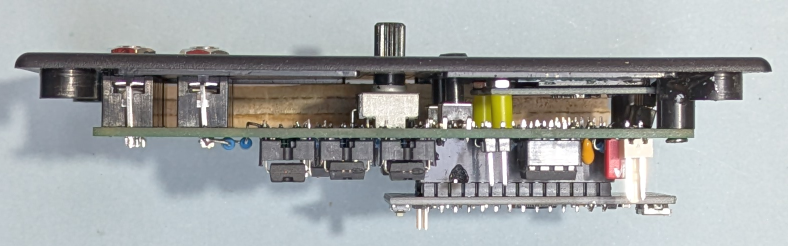

ItsyBitsy M0 synth stand-alone module with (optional) CV input jacks |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

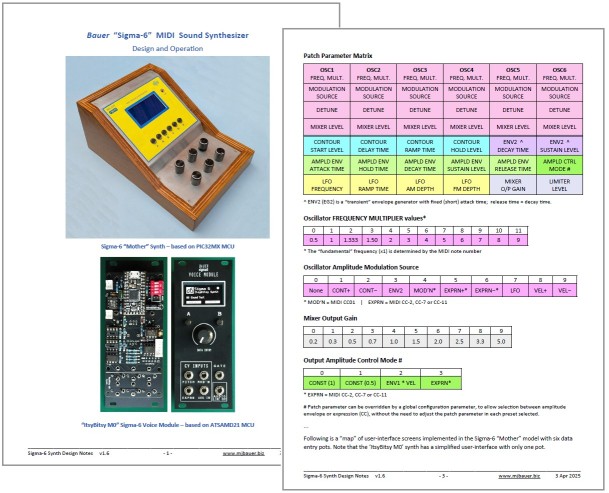

This project is a simple-to-build, low-cost digital mono-synth which I call the "ItsyBitsy M0 Sigma-6". The design is based on Adafruit's SAMD21 "ItsyBitsy M0 Express" micro-controller board. You can substitute a dirt-cheap compatible MCU board (RobotDyn 'SAMD21 M0-Mini' - available on AliExpress). Don't be fooled by the simplicity of the hardware... the firmware implements a complex sound synthesizer comprising 6 oscillators, mixer, 3 envelope shapers, LFO with ramp, variable-gain attenuator (DCA), plus overdrive and reverberation effects. The firmware includes a diverse range of instrument sounds (presets). With two or more "Sigma-6" modules, you can play multi-part music using a MIDI sequencer. Sound quality is excellent using a 12-bit DAC, 32kHz sample rate and 32-bit precision DSP computations. The tone-generator algorithm is immune to aliasing effects (except when overdrive is enabled). You can build a minimal version comprising little more than the SAMD21 MCU board and a MIDI input circuit, or a more elaborate version with a small control panel (OLED display, 2 buttons and a knob). The 'full-featured' build is a 3U rack-mount module with CV and GATE inputs to realize a pseudo-analog "voice module". A number of minimal Sigma-6 modules can be connected via a MIDI bus to a "master controller" board to make a respectable polyphonic synthesizer ... More about that here. The synth software is compiled using the Arduino IDE, so if you have C programming skills, you can easily modify and extend the (open-source) program to suit your own requirements. Details of the 'Sigma 6' synthesizer concept, design and operation can be found in this PDF document... Examples of Sigma-6 Synth build options:

___ Sample Sound Clips 'Two-part Invention' (J.S. Bach) - Duet for 2 Sigma6 synth's, played by a MIDI sequencer. 'The Model' (Kraftwerk) - Produced using PreSonus 'Studio One' Prime v5 (DAW) driving 2 Sigma6 modules. The drum sounds are made with Studio One soft-synth 'Presence'. 'Promenade' (by Jean-Pierre Meyer) - Produced using a MIDI sequencer app driving six Sigma-6 modules, this clip demos a few of the many different instrument sounds (presets) available. 'Variations #1' (by JPM) - More presets in this 4-part sequernce 'Song 1' (by JPM) - Sequence produced in 'CV Mode' ___

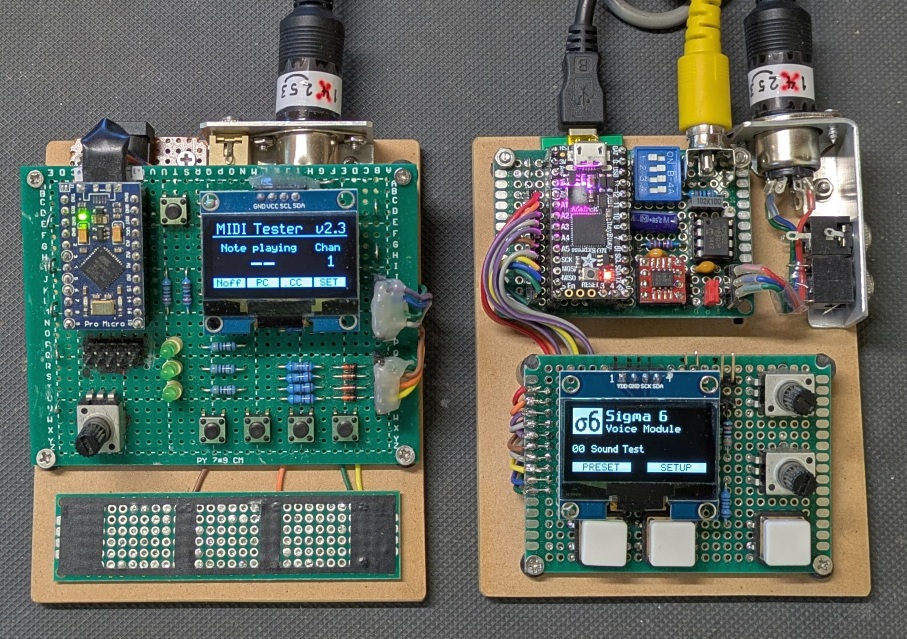

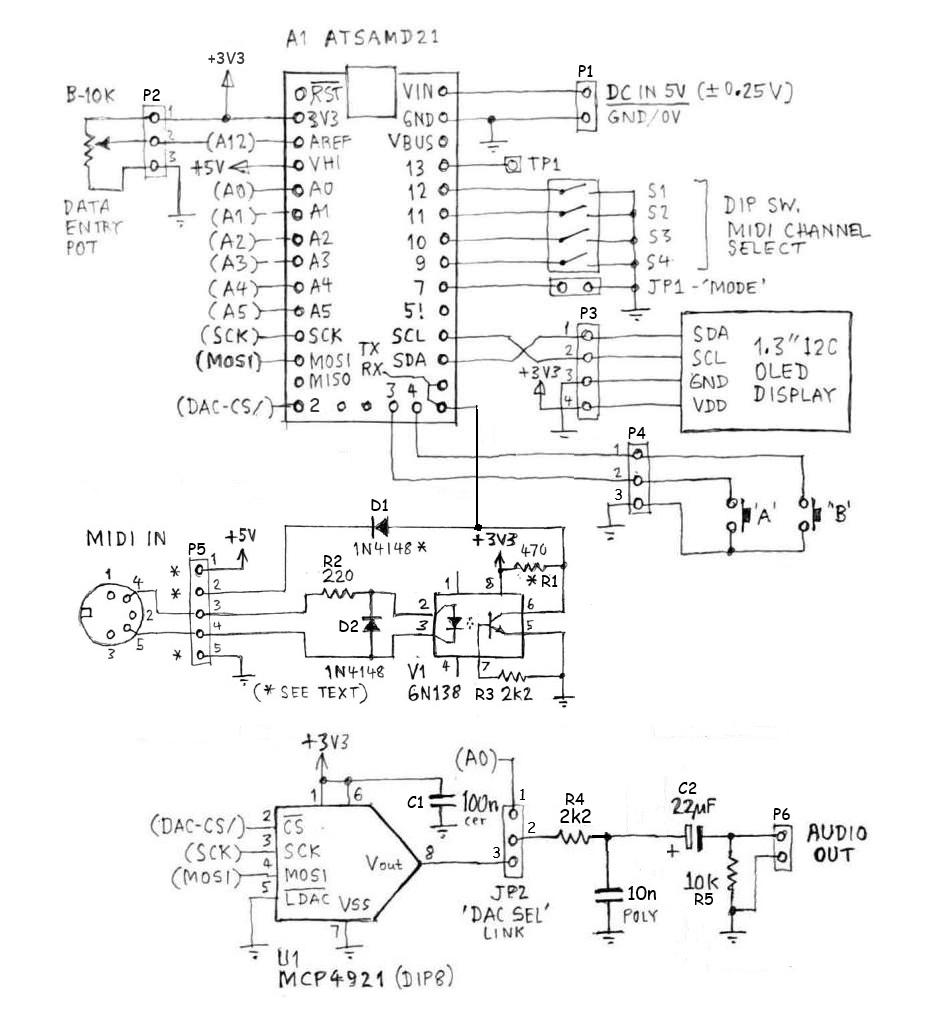

Development & test platform (right) coupled with DIY MIDI Tester/controller (left) Hardware Design Below

is a schematic of the minimum practical build. The

control panel (comprising OLED display, 2 buttons and 'data entry' pot) is

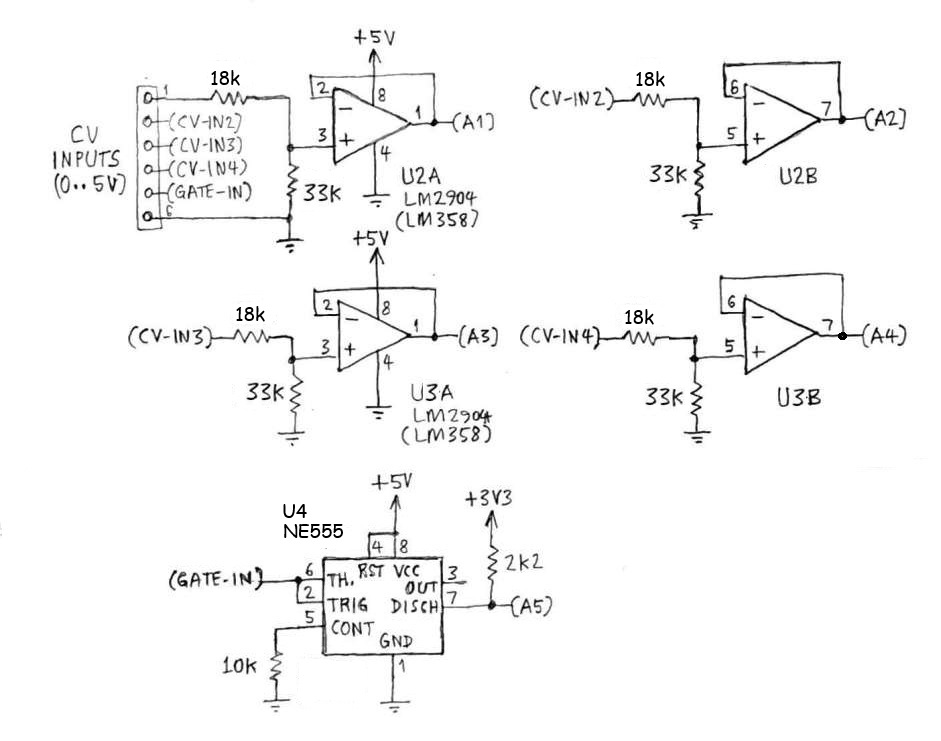

optional, depending on your intended usage.  Hardware variants requiring analog (CV) inputs will need additional circuitry, as shown in part 2 of the schematic below. The PCB will have provision for the extra parts, of course.

SAMD21 ADC inputs are 3.3V full-scale. The external CV inputs are scaled to accept a 0 to +5V signal range. The op-amp buffers ensure that the voltage at the ADC inputs cannot exceed +3.5V, or go negative. The LM2904 and LM358 have a common-mode input range 0 to +3.5V provided Vcc = +5V. The op-amps also allow a high input resistance (50k ohm) at the external CV inputs and a low source resistance feeding into the ADC inputs, as required. The GATE input is fed into a 555 timer IC which is not wired as a timer, but as a Schmitt Trigger to ensure glitch-free transitions. With Vcc = 5.0V, the upper input threshold (VH) is about 2.5V; the lower threshold (VL) about 1.25V, which is 5V logic compatible. The 555 "discharge" output is open-collector which makes a simple 5V to 3.3V level translator using a pull-up resistor. A

low-capacity I2C EEPROM (24LC08B) may be fitted for storage of

persistent data, independent of the SAMD21 MCU which loses its marbles

every time a firmware update is done. The EEPROM is

optional -- User preferences, configuration parameters, CV1 calibration constant, etc, can be hard-coded into the

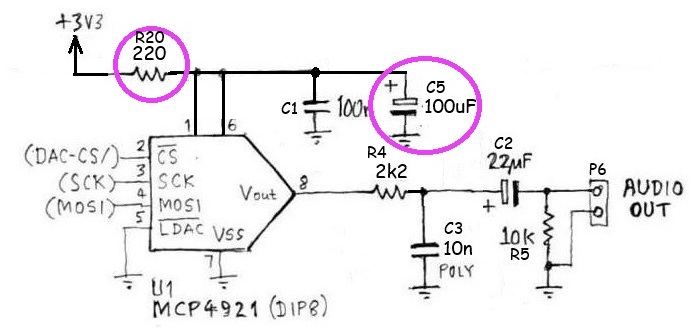

firmware - While testing, a low level audio noise (faint buzz at about 110Hz) became apparent with no sound playing. The noise was caused by the OLED display glitching the +3.3V line which feeds into the VREF input of the audio DAC. This problem occurred with the Robotdyn-based module only... not with the Adafruit MCU. Maybe the Adafruit board uses a superior 3.3V regulator? Anyhow, the latest PCB revision (v3) adds decoupling to the +3.3V line fed into the DAC, as in the circuit below. If you are using an earlier version PCB and the noise bugs you, it is not difficult to modify the PCB to add decoupling components R20 and C5.

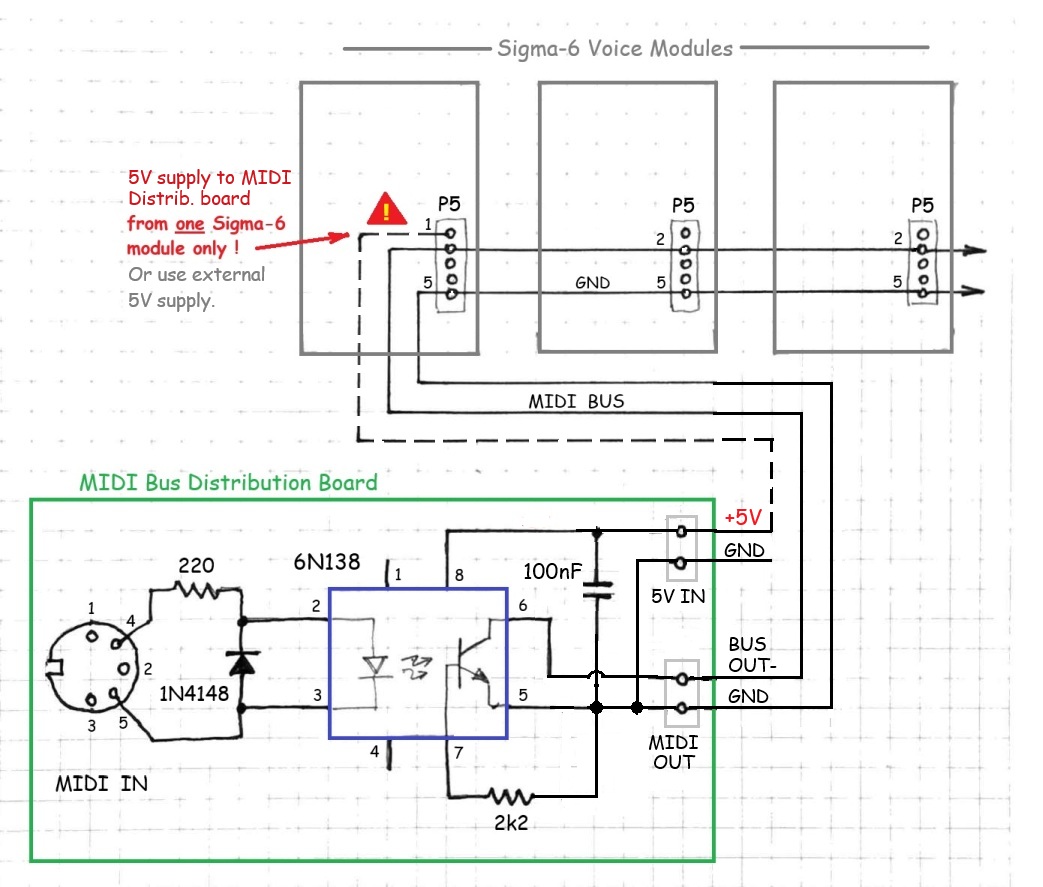

MIDI Input and MIDI Bus Scheme There is a choice of MIDI IN circuit configurations. The opto-coupler (V1) is optional, but recommended for applications where only one Sigma-6 synth module will be connected to a MIDI controller. The MIDI IN circuit was designed with a view to connect multiple modules to a common MIDI bus. For these applications, the opto-coupler (V1) may be omitted. The common bus connection is pin2 of header P5 (and GND of course). Pull-up resistor R1 should be 1k ohm (marked 470 on PCB rev1). The MIDI bus scheme requires a simple "MIDI distribution board" having a standard opto-isolated MIDI IN receiver circuit with an open-collector output, as shown in this schematic...

Note:

It is easily doable to modify one of your Sigma-6 modules to

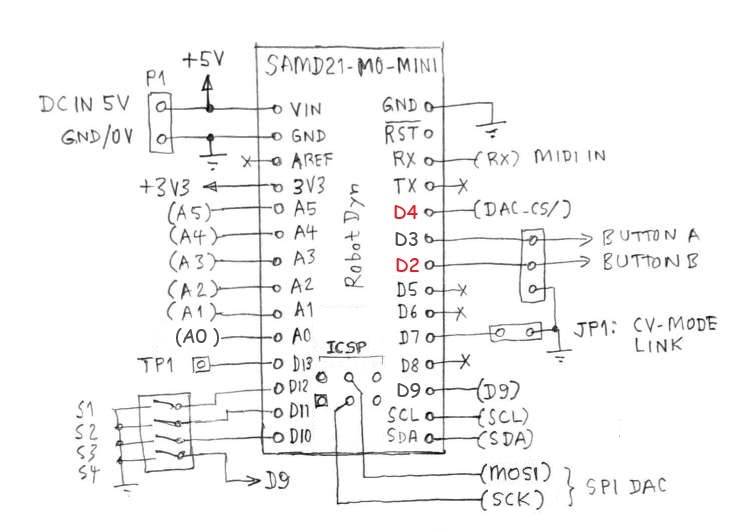

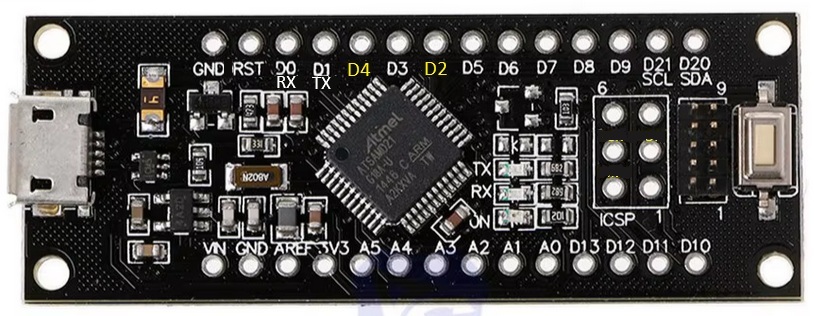

serve as the 'MIDI distribution board'. Low-cost SAMD21 MCU substitute A cheap ATSAMD21 breakout board may be used instead of the Adafruit 'M0 Express' board. These are available on AliExpress using the name "SAMD21 M0-Mini", designed by 'RobotDyn'. Although the RobotDyn board is not physically compatible with the Adafruit 'IstyBitsy M0', all of the required I/O pins (and more) are accessible. This picture shows the signal pin assignments for the "SAMD21 M0-mini" board...

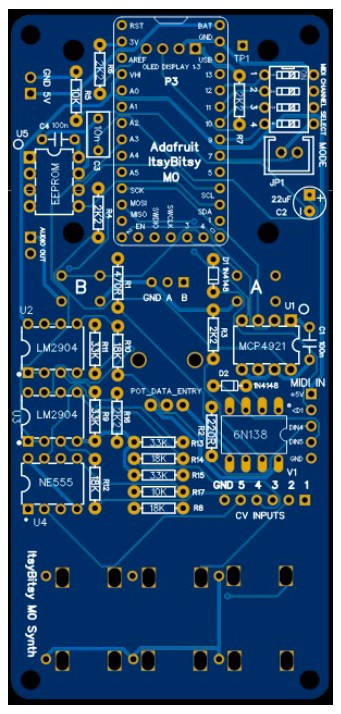

___ Printed Circuit Boards Project collaborator Jean-Pierre Meyer

(in France) has designed circuit boards and other

hardware to facilitate construction and interconnection of synth modules. There are PCB

designs for six build variants, depending on your choice of MCU board and CV jack type, as in this table:

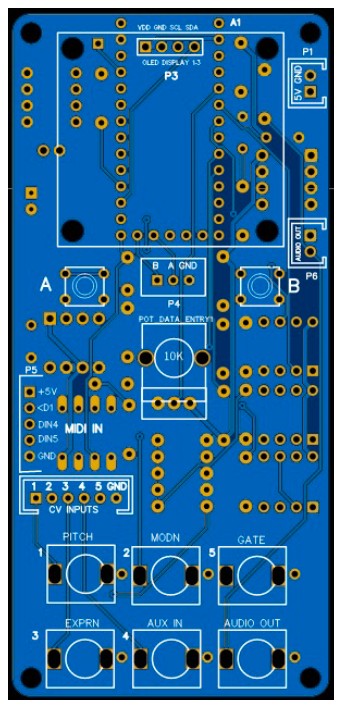

Jack type PJ301M needs a wire link soldered from sleeve lug to GND pad on PCB. Jack type PJ301MB (or compatible type PJ301F) is better suited for PCB mount, but may be harder to obtain. If in doubt, opt for a PCB designed for jack type PJ301M (2A or 2R). This will accept most jack types. This picture shows the board layout (type 2A, v1) and front panel for a Eurorack module.

Gerber files to fabricate PCB based on the Adafruit M0 MCU are ready to download here. Gerber files to fabricate PCB based on the Robodyn M0 MCU are ready to download here. Gerber files to fabricate PCB for the Eurorack

front panel are ready to download here. NB: It is not cost-effective to

post boards overseas. It will cost you less to get your own boards fabricated

in China (including postage). Surplus boards may be offered for

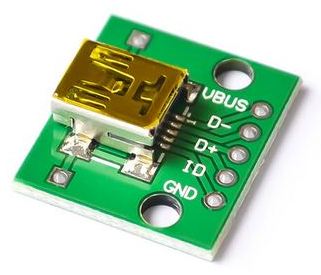

sale in your country... Send email inquiry. Construction notes Be sure to use a polarized pin header and plug for the 5V DC supply (P1). I recommend not to power the module from the MCU USB port, except for firmware updates, for various reasons; e.g. USB "micro-B" sockets are not very robust. For stand-alone Sigma-6 modules, not in a rack, I recommend to use a "mini-B" socket wired to P1 on the PCB for 5V power. USB "mini-B" breakout boards like this are available on AliExpress:

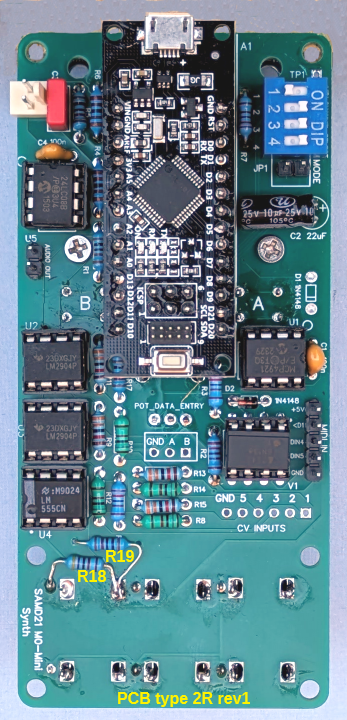

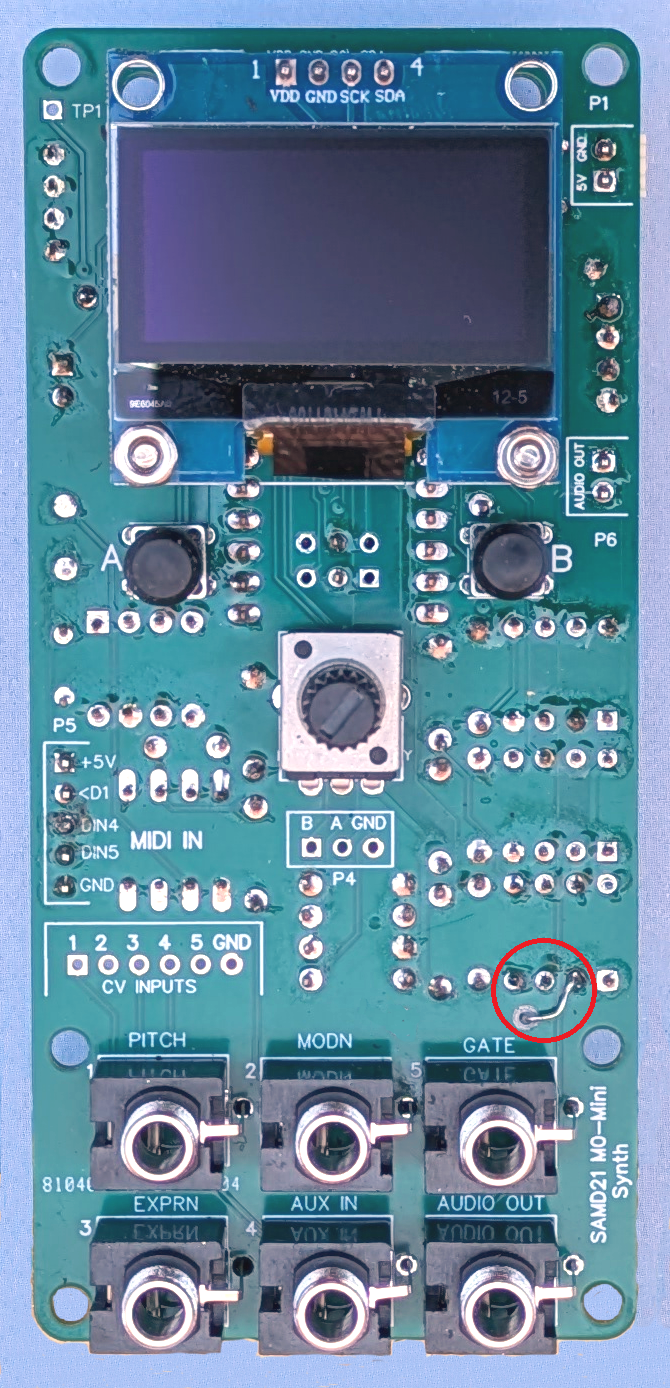

Beware... there are variants of the 1.3 inch OLED display available. To match the PCB footprint (P3), choose a display type with 4 pins in the order: 1=VDD, 2=GND, 3=SCL, 4=SDA. In case your OLED has a 4-pin header already fitted, it may be necessary to bend the pins to make it fit the PCB, or preferably remove the pins. The OLED can be mounted on two spacers 7mm long on the edge opposite to the 4-pin header. Solder the OLED pins (or wires) after mounting on the spacers, to adjust the height at the top edge; also in case the pins don't line up exactly with pads on the PCB. If your PCB uses the Adafruit 'ItsyBitsy M0 Express' MCU, be sure to fit the extra 2 I/O pins needed on the MCU board (digital '3' and '4' on the short edge) and fit a corresponding 2-way socket strip on the PCB. If your PCB uses the RobotDyn 'SAMD21 M0-Mini' MCU, be sure to fit the extra 2 I/O pins required (MOSI and SCK), i.e. two centre pins (3 & 4) in the 6-pin 'ICSP' connector on the MCU board, and fit a corresponding 2-way socket strip on the PCB. (The other 4 pins in the ICSP connector are not needed.) [PCB type 2A & 3A, v1 & v2 only...] There is no provision for R18 or R19 on the PCB. If you intend to use CV control mode, ensure that a 10k and 47k resistor are wired as shown on the schematic. The photos below show PCB type 2R (version 1, modified) with RobotDyn SAMD21 M0-mini MCU fitted.

To suit the height of the CV jacks (PJ301M), the space between the PCB top surface and the inside surface of the front panel should be 10mm. The push-buttons and OLED display are mounted accordingly. Assuming a panel thickness of 1.5 ~ 2mm, tact switches (6 x 6 mm) with an 8mm shaft (12mm overall height) will work if they are raised about 1mm off the PCB surface and fitted with 6mm round button caps. The front panel can be held in place with the CV jacks (nuts screwed on) and a couple of plastic spacers (10mm long) at the opposite end of the PCB (top corners). If your synth module is built without CV jacks, the panel can be held in place with 4 spacers.

Photo: Top panel of stand-alone synth module with PCB (type 2R) assembled Front Panel Decal Panel artwork can be created using Windows Paint, Paint-Shop-Pro, or another image editor. My usual method is to print the decal image on paper, cover it with transparent adhesive film (e.g. bookbinding film), cut holes for knobs, buttons, sockets, etc, then glue it onto the front panel. Sample decal designs are included in the attached Zip folder... download here. Decals in the PDF files will print actual size on A4 size

paper. A blank template is also included for you to design your own

panel artwork, in case you don't like the style or colour schemes of the

samples. The template image resolution is 300dpi. This should print

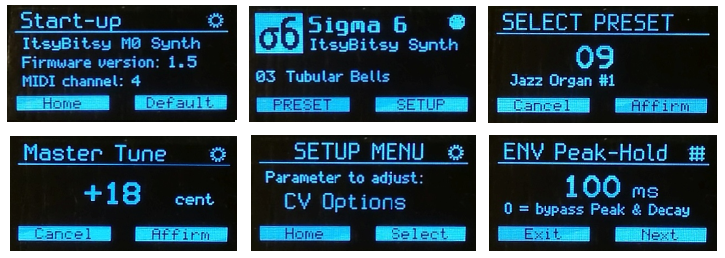

actual size if you specify 300dpi in your printer setup. Control Panel - User Interface The control panel allows selection of presets, of course, and setting of configuration parameters, plus adjustment of some patch parameters. The selected preset determines the basic sound characterstics. It is not feasible to allow all (42) patch parameters to be adjustable with such a simple user-interface... two buttons and a knob! However, the ability to adjust parameters for the amplitude envelope, LFO frequency, vibrato depth, etc, from the front panel, provides essential variability of instrument characteristics.

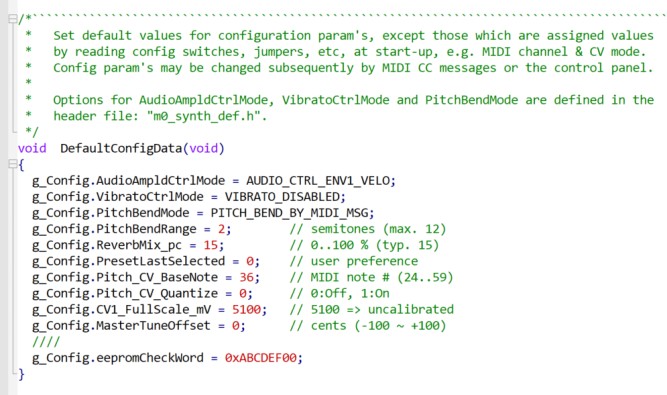

User Guide You don't need one... the control panel is very intuitive to use! (But send me an email inquiry if you find anything in the UI utterly incomprehensible!) Default Configuration Default values for configuration parameters are assigned if the EEPROM contents are erased or corrupted, or if there is no EEPROM fitted. In any case, you can customize the firmware to suit your own preferences. Edit the code in function "DefaultConfigData" in source file "ItsyBitsy_M0_synth.ino". Example:

Whenever your synth is powered up, the display will present a "Start-up" screen with an option to default the configuration. Press Button [B] within 3 seconds from start-up to invoke this function. ... MIDI Implementation The ItsyBitsy M0 Synth recognises MIDI messages: Note-On (with Velocity), Note-Off, Program Change (= Preset select), Pitch-bend, plus Control Change messages summarized in the table below:

Note 1: If Hold Time = 0, the Decay segment is bypassed; i.e. Attack is followed by Sustain. Note 2: 0 = Use Patch parameter; 1 = Fixed (full-scale); 2 = ENV x Velocity; 3 = Expression Note 3: 0 = Vibrato Off; 1 = MIDI Modulation (CC1); 2 = CV4 AUX-IN signal; 3 = Automatic (ramp) Note 4: 0 = Pitch-bend disabled; 1 = MIDI Pitch-bend msg; 2 = CV1 PITCH signal Note 5: Registered param 0 = Pitch-bend Range (semitones); Reg. param 1 = Fine Tuning. Note 6: If a polyphonic MIDI keyboard or sequencer is used to control the synth, it will function Most of the synth parameters settable by MIDI CC messages (70 ~ 89) are also settable using the control panel. Configuration parameters set by CC85 thru CC89 are stored in EEPROM (where fitted) and hence are persistent across power-downs. Parameters set by CC70 thru CC79 are active patch parameters. These settings will default to values defined by the preset patch, whenever a preset is selected. MIDI channel selection ... DIP-switch settings:

[ Legend: 0 = On (closed); 1 = Off (open) ] * The module responds to valid messages addressed to the selected MIDI IN channel and, if MIDI mode is set to 'Omni' (switches set to 0000), it will respond to all messages received, regardless of which channel(s) the messages are addressed to. The module also responds to valid messages addressed to channel 16, regardless of the DIP switch setting, so that the host controller can transmit a "broadcast" message to all modules on the MIDI network simultaneously. NB: Restart the device (reset MCU) after changing MIDI channel or CV mode jumper settings. Legato Operation The Sigma-6 M0 synth complies with the MIDI Specification 1.0 for monophonic devices with respect to Legato operation. However, if 'Legato Mode' is switched off and the attached MIDI controller (keyboard, sequencer, or whatever) operates in POLYphonic mode, then the synth functions as follows... Regardless of a note already playing, if another Note-On event occurs (e.g. a key is pressed), then the new note is initiated with envelopes in the 'attack' phase. The note playing is terminated with envelopes in the 'release' phase when a 'Note-Off' event occurs with the same note number as that used to initiate the note. If a note is already playing (key held down) when a new note is keyed, the note playing will be terminated before the new note is initiated. This is also known as "Multi-Trigger" mode. If 'Legato Mode' is enabled, OR if the attached MIDI controller (keyboard, sequencer, EWI, etc) operates in MONOphonic mode, then the Sigma-6 synth functions as follows... If a note is already playing (key held down) and a new note is keyed, the pitch of the note playing will change according to the note number of the new note. However, the envelope generators will be unaffected... there will be no "repeat attack". If the last note keyed is released before the first note keyed, then the pitch changes back to the first note, but again there will be no "re-attack". Only when the first note is terminated (all keys released) will the envelopes enter the "release" phase. A subsequent Note-On event (key press) will cause the envelopes to enter the "attack" phase, of course. Selecting a preset which has its patch parameter 'Amp Control Mode' set to 'Expression' (3) will enable legato mode, regardless of the global configuration parameter 'Audio Ampld Control Mode' setting. Legato will stay enabled until switched off by a MIDI Control Change 68 message. Legato is also disabled when a preset is selected with patch param 'Amp Control Mode' not set to 'Expression'. Generic presets 24 thru 31, intended primarily for EWI controllers, have this parameter set to 'Expression' so that Legato is enabled. There

is a "build option" in the firmware source code to enable Legato mode

permanently. See #defines near the top of the definitions file:

"m0_synth_def.h". Experiment with your MIDI controller to

determine if you prefer to work with Legato always enabled, or to

switch it on and off as required. Analog (CV) Control Mode The

Sigma-6 "Voice Module" can be configured to operate either as a

voltage-controlled or MIDI-controlled device. The control mode is

initialized at power-on/reset according to jumper JP1 setting. To select CV mode at start-up, place a jumper link on header JP1.

Thereafter, the software switches the mode automatically... In CV mode, oscillator frequency is set by the CV1 (PITCH) input voltage, which covers a 5-octave range. The pitch corresponding to zero volts is set by a configuration parameter 'Pitch CV Base Note', which can be modified by a MIDI message (CC85) or using the control panel. The default setting, note #36 (C2), is hard-coded in the firmware... see function "DefaultConfigData" in source file "ItsyBitsy_M0_synth.ino". Audio output amplitude can be controlled dynamically, either by the synth envelope shaper (ENV1) or by CV3 (EXPRN) if using an external signal. If using CV3 to control expression, set configuration parameter 'Ampld Control Mode' to "Expression" (3). There is also an option which allows CV3 to serve as a "Velocity" signal with 'Ampld Control Mode' set to "ENV1*Velo" (2). With this option enabled, the CV3 input signal is sampled when the GATE input goes High. Any change in CV3 thereafter, i.e. while the note is playing, will have no effect on the audio level because it is controlled only by the envelope shaper. The GATE signal (5V logic) controls all internal envelope shapers: the Amplitude Envelope (ENV1), "Contour" and "Transient" Envelope (ENV2). The envelope generators enter the 'Attack' phase on the GATE signal rising edge (Low to High). They enter the 'Release' phase on the GATE signal falling edge (High to Low). Refer to the "Sigma-6 Design Notes" document for details of the Contour Envelope function. There is an option to "quantize" the CV1 (pitch) input signal so that the oscillator (fundamental) frequency is set to the nearest semitone on the chromatic scale. This may be useful if the external control voltage source is not already tuned to a musical scale, or if it is not well calibrated. Various analog sequencers and random note generators (using sample-and-hold techniques) may fall into this category. Of course, you may prefer not to have the oscillator pitch quantized, in which case turn off the 'quantize' option! This parameter can be set via the Control Panel and/or you can edit the default setting in the firmware. Max. frequency of signal fed into CV1 input Frequency modulation of the synth oscillators can be achieved by adding an AC component to the signal applied to CV1. The AC component (if any) should be band-limited (low-pass filtered) with a cut-off frequency around 250Hz; otherwise aliasing artefacts (unwanted audio frequencies) could occur. CV1 Input Calibration Assuming the module starts up in CV control mode, the 'Start-up' screen will present an option to calibrate the CV1 input. Press Button [A] within 3 seconds from start-up to invoke this function. Apply a stable DC voltage source to the CV1 input. You can use a battery (3 ~ 4.5V), or use the internal +3.3V line, or a voltage-divider on the +5V supply to obtain a voltage in the range 3 ~ 4.5V. Measure the voltage applied to the CV1 input jack using an accurate voltmeter. Call this "actual_input_mV". You could use a 3½ digit DMM (full-scale 3.999V) if the voltage source is less than 4V, but these are rarely better than 0.5% accurate on DC volts. Preferably, use a 4½ digit DMM with DC accuracy 0.1% or better. Wait a few seonds for the CV1 voltage indicated on the display to stabilize. Call this "adc_reading_mV". The ADC reading assumes CV1 input full-scale is 5100mV, based on the voltage-divider (18k + 33k) and ADC reference voltage (3.3V). Calculate the actual (calibrated) full-scale value using this formula... full_scale_mV = 5100 × actual_input_mV ÷ adc_reading_mV Enter this value (rounded to the nearest integer) in the function "DefaultConfigData", replacing the existing default value (5100) as in this example: g_Config.CV1_FullScale_mV = 5073; Compile and upload the firmware to your synth board. Restart the module and default the configuration... (see section "Default Configuration", above). Note: Firmware v1.6 (and later versions) will show both an 'Uncalibrated" reading and an "Adjusted" reading. The uncalibrated value

is "adc_reading_mV" to put in the formula above. After the calibration

procedure is done, the adjusted reading should be equal to

the voltage source measured at the CV1 input (±5 mV). Firmware Installation Follow instructions in the 'READ-ME' file on GitHub here: Sigma-6 Synth software repository .. Thanks for taking

an interest in this project. Feel

free to send comments and queries. See MJB's Index Page Send email inquiries, comments, suggestions, etc, to... Last update: August 2025 ___ |